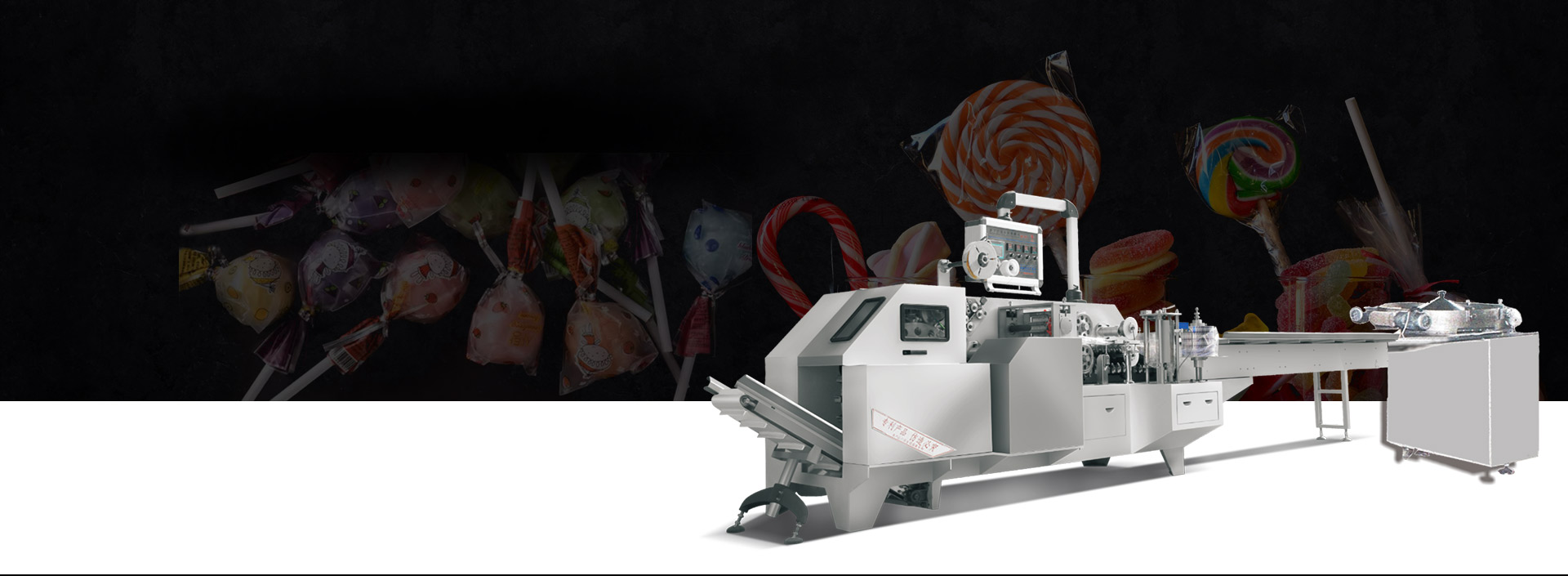

تلعب القدرة الإنتاجية لمعدات الحلوى وخطوط إنتاج الحلوى دورًا مهمًا في تطوير الشركات المصنعة، ولكن في السوق، يمكن أن تلعب دورًا مستقرًا في تطوير قدرة إنتاج الشركات المصنعة، وهو أمر كبير جدًا. هذا يوضح أن القدرة الإنتاجية يمكن أن تلعب دورًا كبيرًا في تطوير الشركات المصنعة ويمكن أن توفر الزخم لتطوير الشركات المصنعة. توفير فرص تطوير السوق للشركات المصنعة لتعزيز وجودها في السوق بشكل أكبر، ثم كيفية تحسين القدرة الإنتاجية لخطوط إنتاج الحلوى.

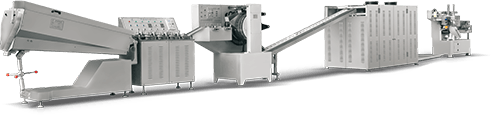

من حيث طرق الإنتاج، تحتاج خطوط إنتاج الحلوى إلى زيادة القدرة الإنتاجية، ويجب تحسين طريقة الإنتاج بأكملها للتغيير. الطريقة التقليدية غير مستدامة. على سبيل المثال، سيتم القضاء على طريقة الإنتاج والمعالجة البطيئة واستبدالها بطريقة إنتاج مستمرة. على الأساس الأصلي، يمكن زيادة القدرة الإنتاجية ويمكن الحصول على المزيد من القيمة السوقية. على الرغم من أن التغيير فترة صعبة. ومع ذلك، فإن عملية الارتفاع المطرد يمكن أن تجلب مكاسب جيدة للشركات المصنعة، الأمر الذي يتطلب من الشركات المصنعة المثابرة.

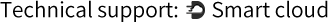

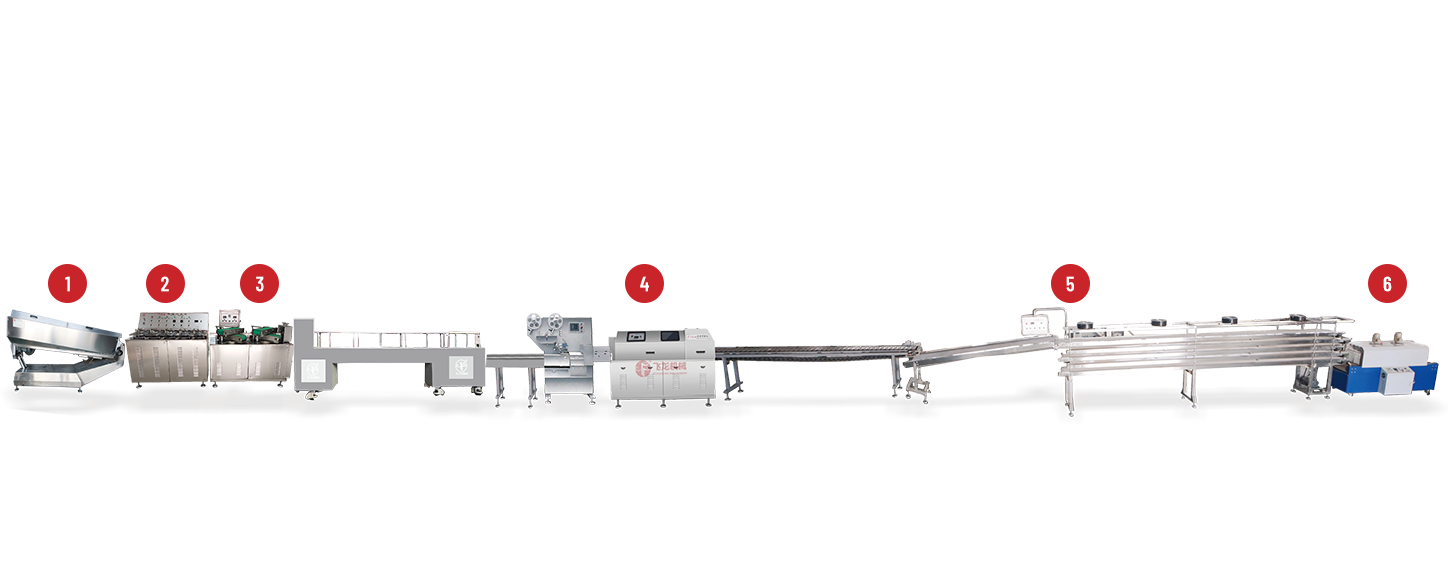

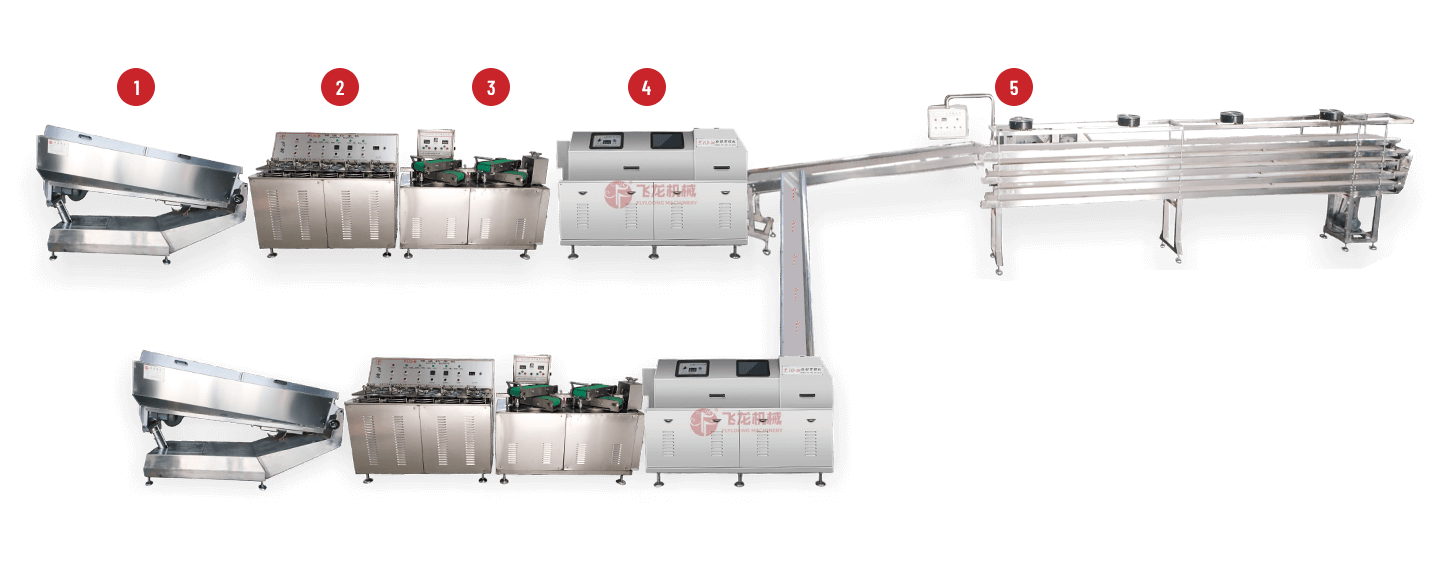

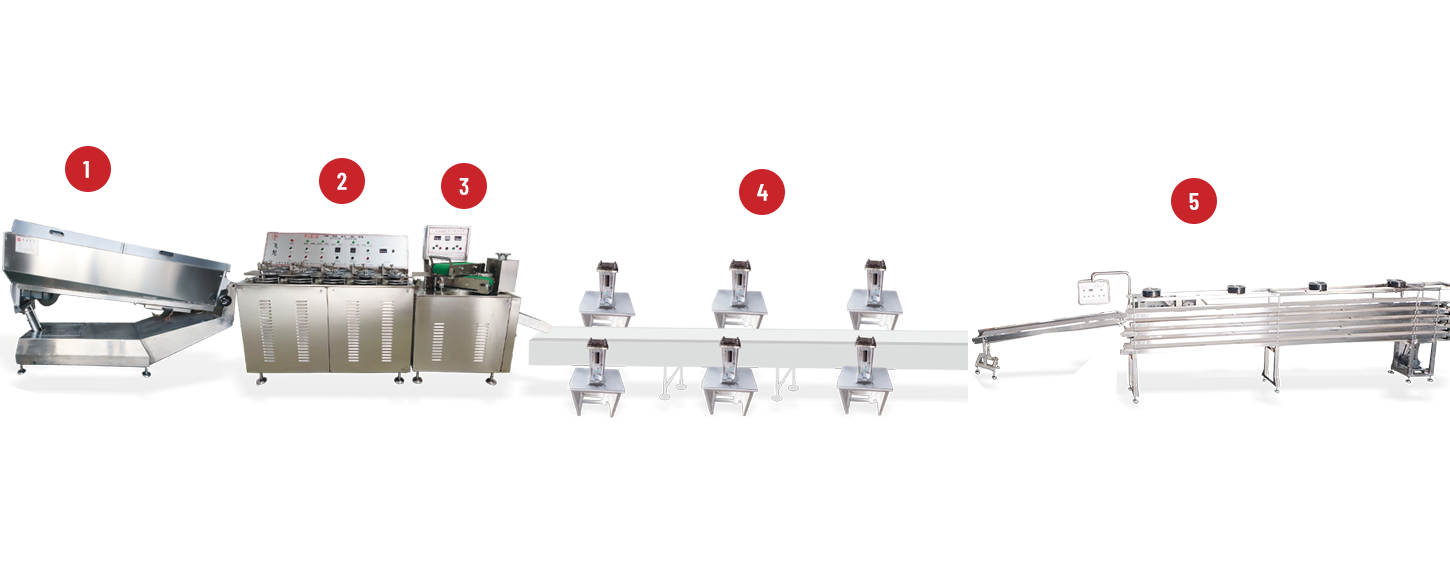

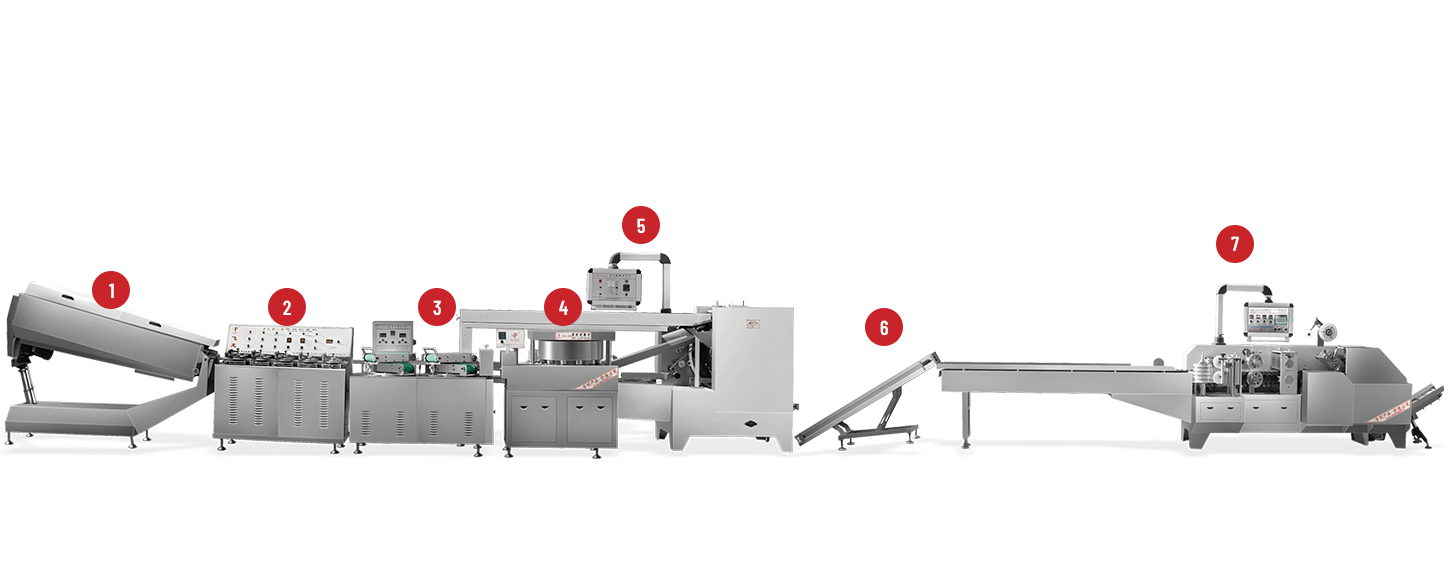

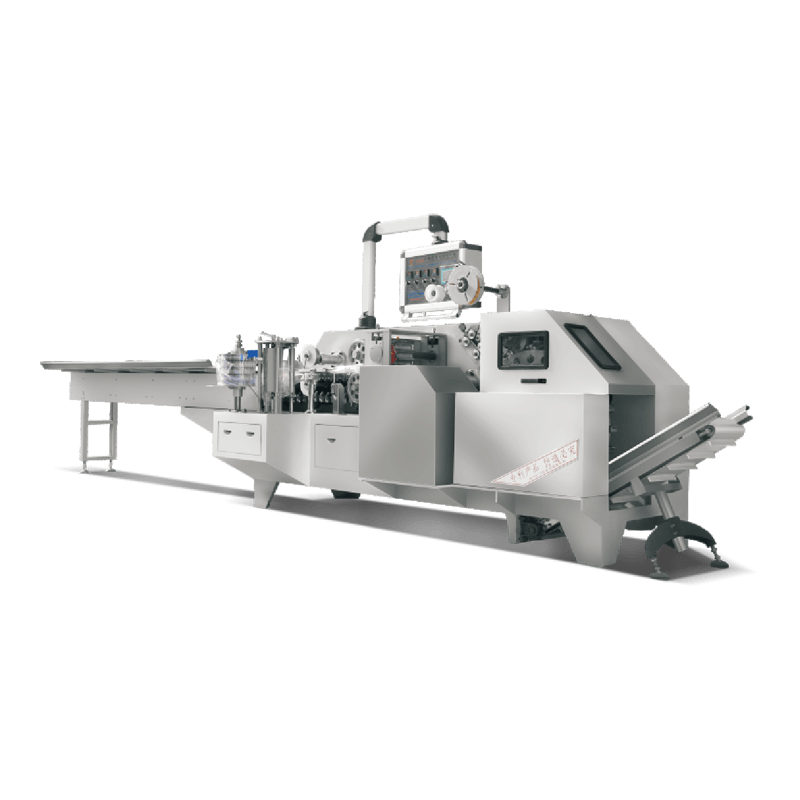

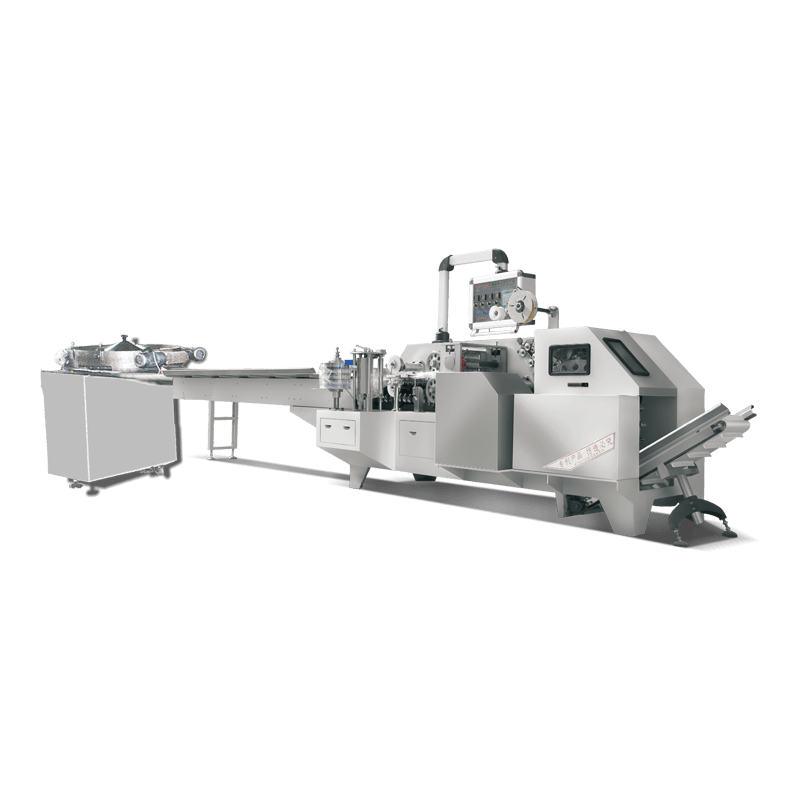

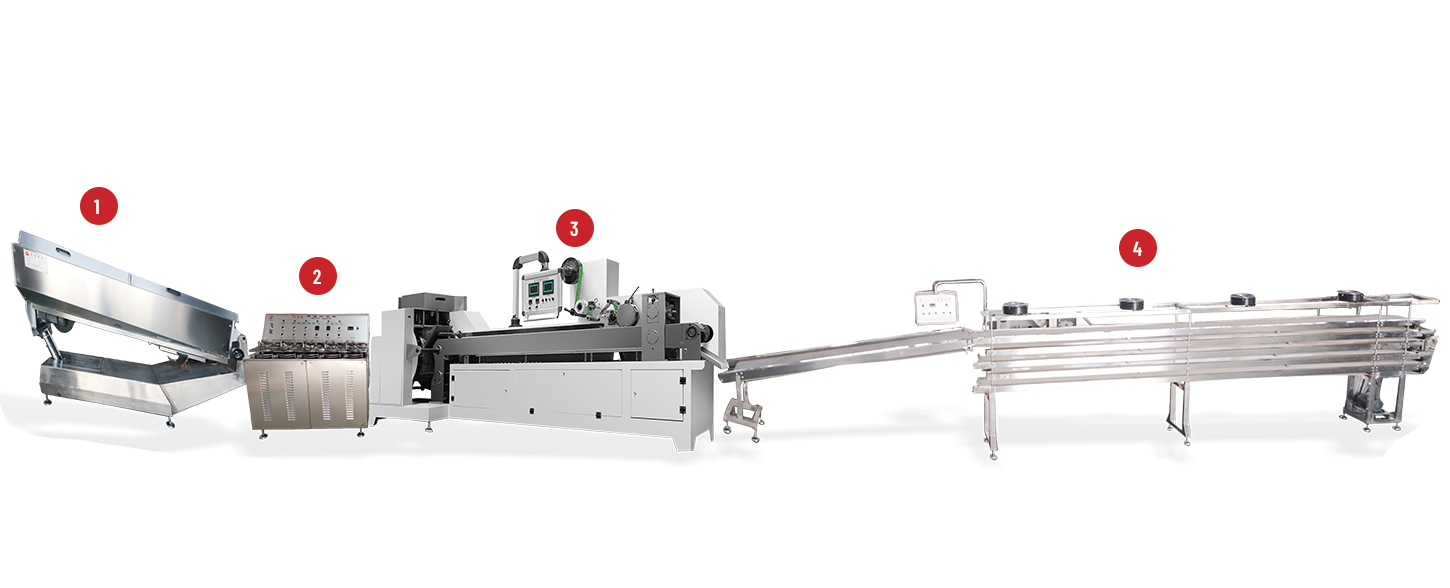

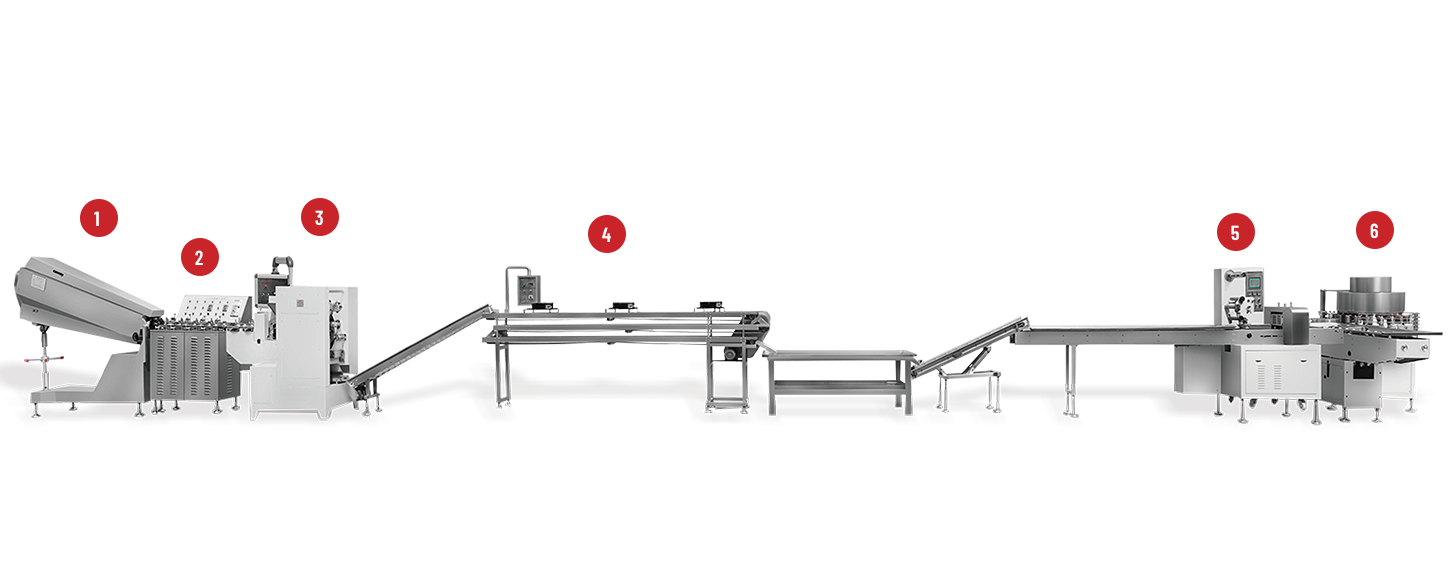

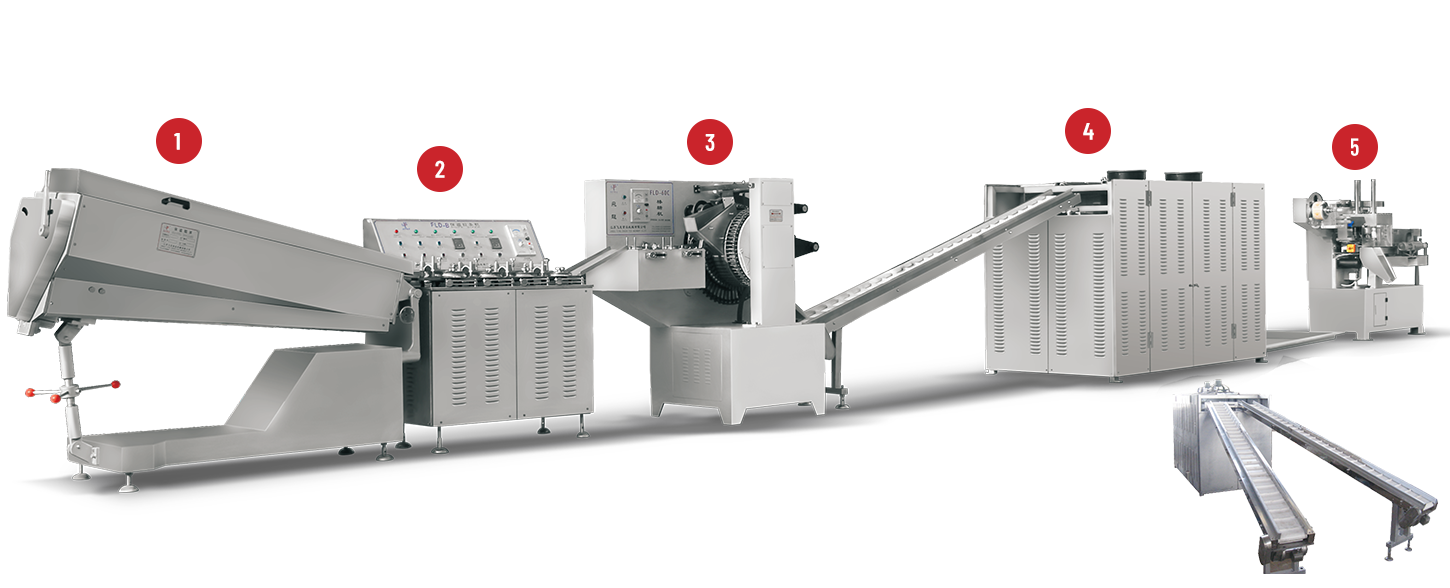

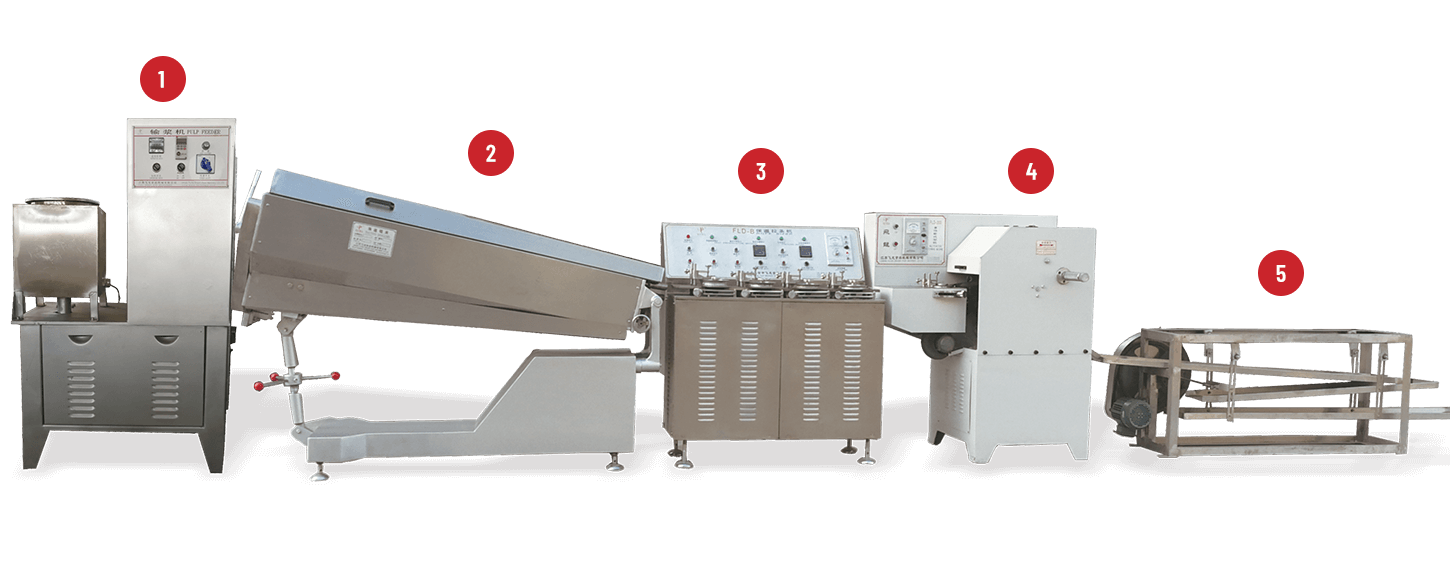

التركيب: عجلة السكر، عصا السكر، مكشطة السكر، دلو السكر، مكشطة السكر، دلو السكر، رأس دوار، عجلة قطع السكر. الختم هو طريقة لتشكيل الحلوى الصلبة. في الأيام الأولى، اعتمدت آلات حلوى الأرز التشكيل بالثقب المتقطع، والذي يمكنه معالجة حلوى واحدة فقط في كل مرة، وكانت كفاءة الإنتاج منخفضة للغاية. في الوقت الحاضر، يتم استخدام ماكينة الختم الساخن الدوارة المستمرة على نطاق واسع، والتي يمكنها ختم المزيد من الحلوى في نفس الوقت، مما يحسن كفاءة الإنتاج بشكل كبير.

مبدأ العمل: بعد التبريد والتسوية، تدخل قطعة الحلوى إلى ماكينة التشكيل، وتحت تأثير الاحتكاك، يتم تغذية قطعة الحلوى في رأس العجلة. يتم لفها في الحافة الخارجية لأخدود التشكيل. بعد الضغط على عجلة السكر، يتم ضغط قطعة الحلوى في أخدود التشكيل وكسرها. في نفس الوقت، تتحرك قطعة الحلوى للأمام تحت ضغط الكاميرا، وتدفع قطعة الحلوى إلى فتحة التشكيل، وتدخل إلى قادوس تفريغ السكر بملعقة، وتسقط وتهتز. في المنخل، يتم تبريد الحلوى ويمكن تعبئتها.

إزالة الغبار، الاستخدام طويل الأمد لآلات الحلوى سيترك الكثير من الغبار. إذا كانت المعدات مغطاة بالغبار واستمرت في العمل، فلن يؤثر ذلك على طعام الحلوى فحسب، بل سيواجه أيضًا مشاكل كبيرة في معالجة تبديد الحرارة للمحرك. يسد الغبار فتحات تبديد الحرارة، بحيث يمكن للمحرك الاستمرار في إكمال المعالجة في درجة حرارة عالية، مما يؤثر بشكل خطير على عمر خدمة المحرك. صيانة المعدات ضرورية. يجب تنظيف كل الغبار، بحيث لا تؤثر المعالجة المستمرة على درجة حرارة عمل المحرك.

يلعب تزييت الأجزاء والمكونات الداخلية والملحقات لآلات الحلوى دورًا مهمًا في أداء الجهاز بالكامل. ومع ذلك، أثناء المعالجة المستمرة، ستتآكل الأجزاء البالية بشكل أكثر خطورة وتحتاج إلى التشحيم، مما لا يقلل من درجة تآكل الأجزاء فحسب، بل يلعب أيضًا دورًا وقائيًا ويطيل عمر خدمة المعدات.

عربى

عربى

English

English 中文简体

中文简体 русский

русский Français

Français Español

Español عربى

عربى

+86-(0)515-8465666

+86-(0)515-8465666 +86-(0)515-85566996

+86-(0)515-85566996 +86-138 1559 9708

+86-138 1559 9708 flyloong@flyloongcn.com

flyloong@flyloongcn.com

الصفحة الرئيسية

الصفحة الرئيسية